Elevating Global Standards: How China's Top 3D Printers Redefine Business Quality

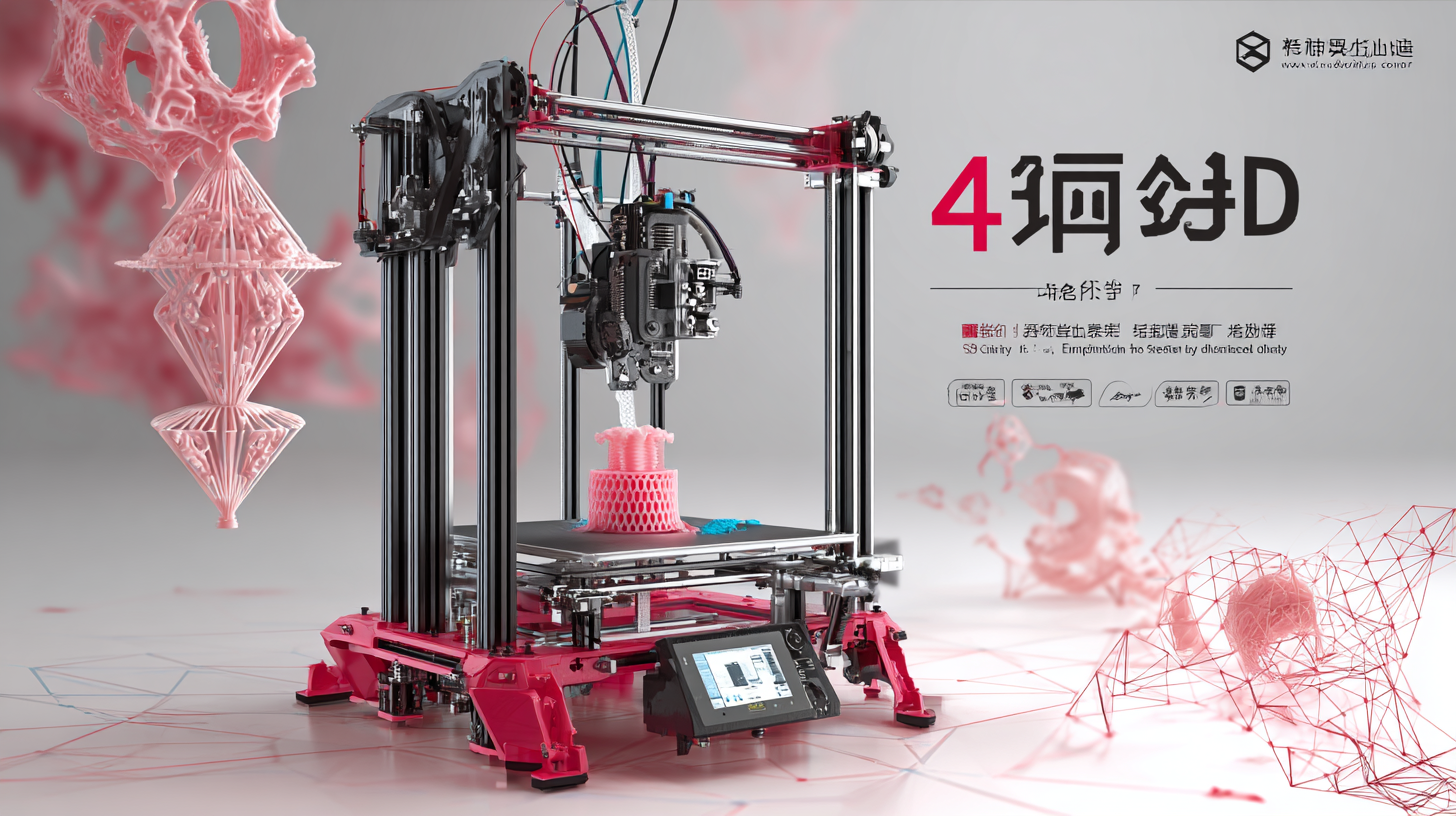

As the global market increasingly recognizes the pivotal role of additive manufacturing, China's advancements in 3D printer technology have emerged as a game-changer for businesses worldwide. According to a recent report by MarketsandMarkets, the 3D printing market is projected to grow from $13.7 billion in 2020 to $62.79 billion by 2028, underscoring the accelerating adoption of 3D printers for business across various sectors. China's top manufacturers are not only enhancing production efficiency but are also redefining quality standards with their innovative machinery. By integrating cutting-edge technologies and optimizing material use, these 3D printers are enabling companies to reduce waste and streamline operations.

This blog will explore how Chinese 3D printers are elevating global business quality, setting new benchmarks for performance, and paving the way for future advancements in the industry.

Exploring the Rise of China's Leading 3D Printers in the Global Market

China's emergence as a leader in the 3D printing industry is redefining global business quality and opening new markets. With expectations for the 3D printing sector to exceed $40 billion by 2030, Chinese manufacturers are at the forefront of this technological revolution. Their innovative capabilities are not only enhancing production efficiency but also establishing new standards across various industries. As major players in the market, these companies are driving advancements that simplify complex manufacturing processes and improve product quality.

Tip: To stay ahead in this evolving landscape, businesses should consider adopting 3D printing technologies to enhance their operational efficiency. By integrating additive manufacturing into their production lines, companies can reduce waste and optimize their supply chains.

As China continues to innovate, the influence of its 3D printing industry is expected to ripple across the globe, fostering collaboration and competition. When businesses leverage these advanced technologies, they can capitalize on emerging trends, such as the increasing demand for lightweight materials in aerospace applications, which is projected to see significant growth in the coming years.

Tip: Regularly evaluate the latest 3D printing technologies and market reports to identify opportunities for incorporating them into your business strategy. Understanding market trends and consumer preferences can offer valuable insights into where to invest for future growth.

Elevating Global Standards: How China's Top 3D Printers Redefine Business Quality

| Printer Model | Build Volume (mm³) | Layer Height (µm) | Material Compatibility | Market Position |

|---|---|---|---|---|

| Model A | 300 x 300 x 400 | 50 | PLA, ABS, PETG | Leader |

| Model B | 250 x 250 x 300 | 75 | Nylon, TPU | Emerging |

| Model C | 500 x 500 x 500 | 100 | Metal, Ceramics | Innovator |

| Model D | 400 x 400 x 600 | 60 | Composite Materials | Rising Star |

Key Innovations Driving Quality Improvements in 3D Printing Technology

The rapid advancements in 3D printing technology are reshaping global business standards, particularly through key innovations that improve quality. In recent years, the integration of artificial intelligence and the Internet of Things has revolutionized the way businesses approach manufacturing and product design. These technologies provide real-time data analysis, enhancing precision and facilitating faster decision-making processes. As a result, 3D printers are now capable of producing highly customized products that meet specific consumer demands, leading to improved overall quality.

The rapid advancements in 3D printing technology are reshaping global business standards, particularly through key innovations that improve quality. In recent years, the integration of artificial intelligence and the Internet of Things has revolutionized the way businesses approach manufacturing and product design. These technologies provide real-time data analysis, enhancing precision and facilitating faster decision-making processes. As a result, 3D printers are now capable of producing highly customized products that meet specific consumer demands, leading to improved overall quality.

One notable trend is the rise of dental 3D printing materials, which are transforming prosthodontics by allowing for unprecedented levels of customization and precision. This shift not only streamlines production but also significantly enhances patient outcomes. Companies focusing on these innovations are better positioned to meet the growing demand for personalized medical solutions.

Tip: To leverage the benefits of advanced 3D printing, businesses should invest in training staff on the latest technologies and materials. Emphasizing collaboration between design and production teams can also lead to innovative products that meet today's quality standards. Additionally, keeping abreast of emerging trends and consumer preferences will enable businesses to stay competitive in an evolving marketplace.

Impact of China's 3D Printing Advancements on Global Business Standards

China's advancements in 3D printing technology are not just transforming its domestic landscape but are also setting new benchmarks for global business quality. Recent moves by major industry players in the 3D printing sector illustrate a vibrant commitment to innovation and scalability, with significant investments leading to rapid growth. For example, a company recently achieved a remarkable milestone, reaching over a million dollars in annual recurring revenue in just 45 days, bolstered by a substantial funding round to support the international commercialization of large-scale 3D printing models.

This push not only reflects China's ambition to lead in the 3D printing arena but also signifies a shift in global business standards where quality and efficiency are paramount. As companies around the world begin to adopt these advanced printing technologies, the criteria for success are evolving. The integration of these high-quality 3D printing solutions into various industries promises to enhance product design, reduce waste, and ultimately contribute to more sustainable manufacturing practices. The impact of these developments will resonate beyond borders, encouraging a reevaluation of best practices in business operations globally.

2025 Industry Trends: The Future Landscape of 3D Printing in China

The 3D printing landscape in China is evolving rapidly, driven by significant advancements in additive manufacturing technology. As of 2025, the market for this technology is projected to expand dramatically, with segments covering hardware, software, services, and materials gaining substantial traction. Applications across diverse industries like healthcare, automotive, aerospace, and construction are set to redefine quality standards and operational efficiencies. The integration of 3D printing in these sectors showcases its potential to facilitate rapid prototyping and personalized manufacturing, ultimately revolutionizing supply chain practices.

Regional insights reveal that demand for 3D printing is surging, particularly in urbanized areas where innovation thrives. China's commitment to advancing technology positions it as a global leader in 3D printing, enhancing its competitive edge in manufacturing and design.

Events such as the Mobile World Congress 2025 highlight the collaboration between key research institutions and industries, underscoring the importance of continuous research in shaping future trends.

As we look ahead, the role of additive manufacturing in creating sustainable solutions and reshaping traditional practices will be pivotal, making it imperative for businesses to adapt and invest in these transformative technologies.

Practical Tips for Businesses to Leverage China's 3D Printing Innovations

China’s advancements in 3D printing technology are not just impressive; they are revolutionizing business quality across various industries. To effectively leverage these innovations, businesses must consider strategic approaches to integration. One practical tip is to invest in training staff on the latest 3D printing software and techniques. By upskilling employees, companies can ensure they maximize the potential of this technology, leading to efficient production processes and reduced costs.

Another essential tip is to collaborate with Chinese manufacturers specializing in 3D printing. Establishing partnerships can enable businesses to tap into local expertise and cutting-edge technologies, which can enhance production capabilities significantly. Companies should also explore customization options available through 3D printing, as this allows for more tailored products that meet specific customer demands, giving them a competitive edge in the market. Embracing these tips can help businesses not only improve their quality standards but also position themselves as leaders in their respective fields.